TECHNOLOGY

IMMERSIVE TECH

USE CASE

TOOL

CLIENT

ACCIONA AGUAS is a leading company with the capacity to design, build and operate drinking water treatment plants, wastewater treatment plants, tertiary treatment for reuse and reverse osmosis desalination plants.

GOAL ACHIEVED

Facilitate the maintenance processes of their water pumps and other machinery by creating a Mixed Reality Hyper-Experience and using Microsoft Hololens.

Mixed Reality: the new companion of maintenance

Acciona Aguas, a business area of the multinational giant Acciona, relied on DeuSens Hyperexpertise to carry out an ambitious Industry 4.0 pilot project. In this case it consisted of a project that aimed to explore the optimization and improvement in the maintenance processes of their water pumps and other machinery, introducing in the process a technology as versatile and interesting as Mixed Reality.

At the time of this project, Mixed Reality was a technology little present in society and therefore very little known by the general public. Therefore, getting this opportunity to implement it for a large company like Acciona, was a challenge that we faced by making use of all our knowledge and skills.

"Gestural interaction and voice commands bring a significant increase in the efficiency of technicians"

The end of paper manuals?

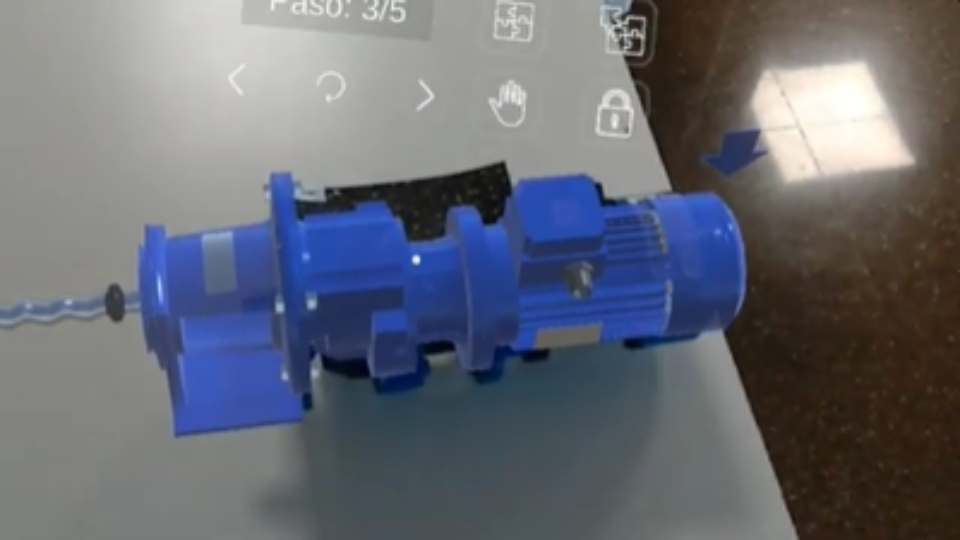

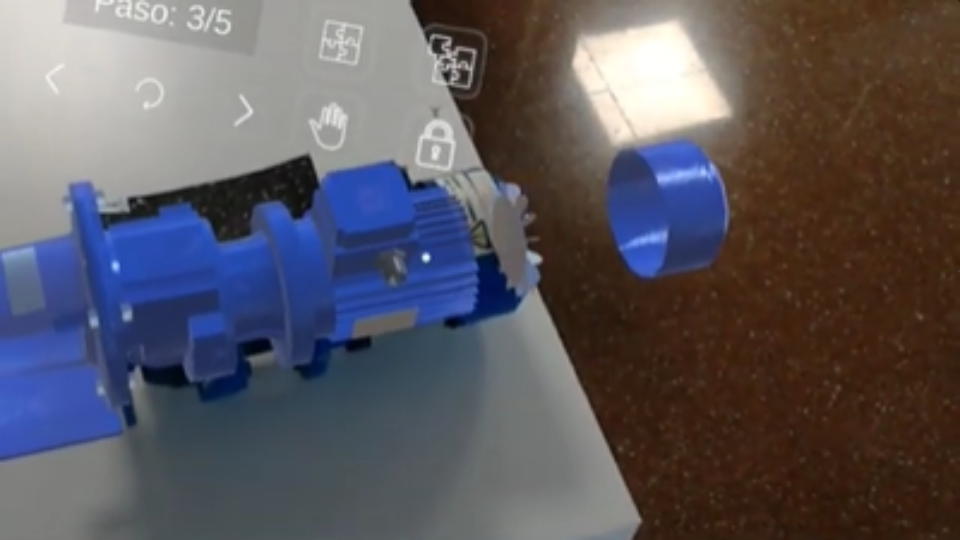

The project approach consisted in generating a 3D "virtual twin" of the water pump that was to be serviced, superimposing it on the real physical pump. In this way, the technician who was going to perform the maintenance, could visualize, through Mixed Reality glasses, a virtual recreation of the water pump at the same time as the real water pump.

Thanks to this, the technician had an identical replica of the object, which, through 3D animations was showing him the steps to follow and how to perform them to finish the maintenance correctly. Through the use of this technology, the operator had a methodology that did not give rise to error, since he could check step by step the process to execute and perform it in real time, visualizing a full-scale representation of the parts to assemble and disassemble that serves as a guide.

It should be noted that one of the main objectives of the project was to offer technicians an environment in which they could obtain the vital and necessary information to complete the task, and at the same time, have their hands free to work with them. In this way, we implemented the possibility of using voice commands and gestural interaction, achieving that the technicians, without having to touch the Mixed Reality glasses, performed the work much faster.

In addition to the use of this project for maintenance "on the fly", the same project could also be used for the training and coaching of new staff of the company. We achieved this by incorporating a functionality to the application by which it was not necessary the presence of the real physical pump to be able to visualize the 3D model and the representation of assembly and disassembly with all the steps to follow. In this way, any technician in training phase, could visualize the complete process through the 3D representation of the pump and learn its phases, without the constant need to have another experienced technician to teach him.

Ready to take the leap to hyperexperience?

SIMILAR PROJECTS

3D video, AR and holograms for trade fairs | Interactive booth for Fluidra

Distrito AR | Interactive Augmented Reality Web Experiences in Telefónica District

Virtual Showroom for AFYDAD | The ecommerce revolution

Virtual Reality in the Automotive Industry | CEFA's 70th Anniversary

RETURN

RETURN