In the era of Industry 5.0, where digitization and automation are radically transforming industrial processes, an innovative concept is emerging that promises to boost efficiency and strategic decision-making: digital twins. These sophisticated virtual models, which accurately replicate the behavior and characteristics of a physical system in real time, have opened up an unprecedented horizon of possibilities.

Digital twins, grounded in technologies such as the Internet of Things (IoT), artificial intelligence (AI) and Big Data processing, have become the cornerstone of Industry 5.0. By leveraging connectivity and advanced analytics capabilities, digital twins allow organizations to simulate, monitor and optimize their operations virtually, before even implementing changes in the physical world.

In this blog, we will explain in detail the fundamentals and implementation of digital twins in the context of Industry 5.0.

Definition and characteristics of a digital twin

Digital twins are the key that unlocks the intelligent transformation of Industry 5.0, enabling process optimization, informed decision making and the drive towards operational excellence.

Definition of digital twin

Digital twins are virtual representations that accurately recreate and simulate the behavior and characteristics of a physical system or process in real time. These digital models are the backbone of Industry 5.0 and enable tighter integration between the physical and digital worlds.

In essence, a digital twin is a virtual replica of a physical object, equipment, process or system. Through real-time data capture and constant feedback, digital twins provide accurate and up-to-date information on the status, performance and behavior of their physical counterpart. This information is used for analysis, optimization and informed decision making in a variety of industrial contexts.

Functioning and elements of a digital twin

Creating a digital twin involves the integration of multiple technology components and the continuous capture of relevant data. Some of the key elements of a digital twin include:

- IoT sensors and devices: They collect data from the physical world, such as temperature, vibration, pressure, flow measurements, among others, and transmit them to the digital twin platform

- Digital twin platform: It is the central core that processes, stores and analyzes the captured data.

- Models and algorithms: Allow simulating the behavior and interactions of the physical system in the digital twin.

- Connectivity and communication: Facilitates data transmission between the components of the digital twin and the physical infrastructure.

- Virtual representation: After generating the data model, the virtualization of the simulation obtained from the data is displayed. This virtual representation of the digital twin can be done through technologies such as Virtual Reality or Augmented Reality or 3D software.

Implementation of digital twins in industry 5.0

In the era of Industry 5.0, digital twins have become a critical piece in driving the digital transformation of enterprises. By leveraging connectivity, advanced analytics and simulation technologies, digital twins offer a number of incredible competitive advantages.

Benefits of digital twins in industry 5.0

-

Process and resource optimization: Digital twins can identify bottlenecks, inefficiencies and opportunities for improvement in industrial processes. By simulating different scenarios and performing advanced data analysis, organizations can optimize their operations, improve efficiency and reduce costs.

-

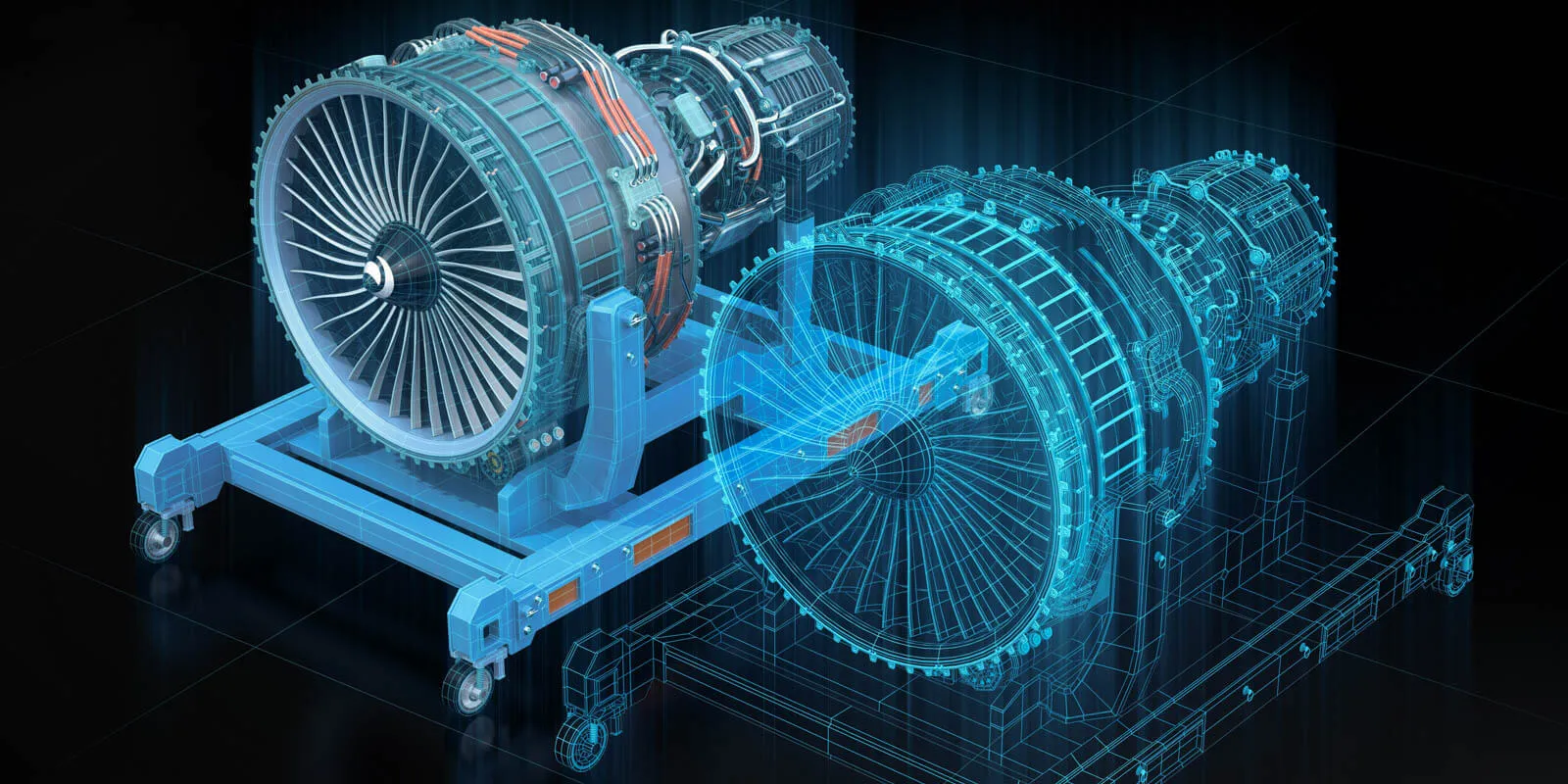

Predictive maintenance and downtime reduction: Digital twins constantly monitor the status of physical assets and generate real-time alerts about potential problems or maintenance needs. This enables the implementation of predictive maintenance strategies, which helps reduce unplanned downtime and maximize equipment availability.

-

Improved strategic decision making: Digital twins provide accurate and up-to-date information on the performance and behavior of physical systems. This enables business leaders to make more informed and strategic decisions, anticipate scenarios and evaluate different strategies more accurately.

-

Virtual design and prototyping: Digital twins enable virtual testing and validation of designs before physical implementation. This speeds up the product development cycle, reduces costs associated with errors and rework, and improves design quality and efficiency.

-

Scenario simulation and risk management: Digital twins make it possible to simulate different scenarios and assess their impact in real time. This helps to foresee and manage potential risks, evaluate alternative strategies and optimize operations planning in complex environments.

Examples of the use of digital twins in companies

Technology to optimize the operation of water treatment plants

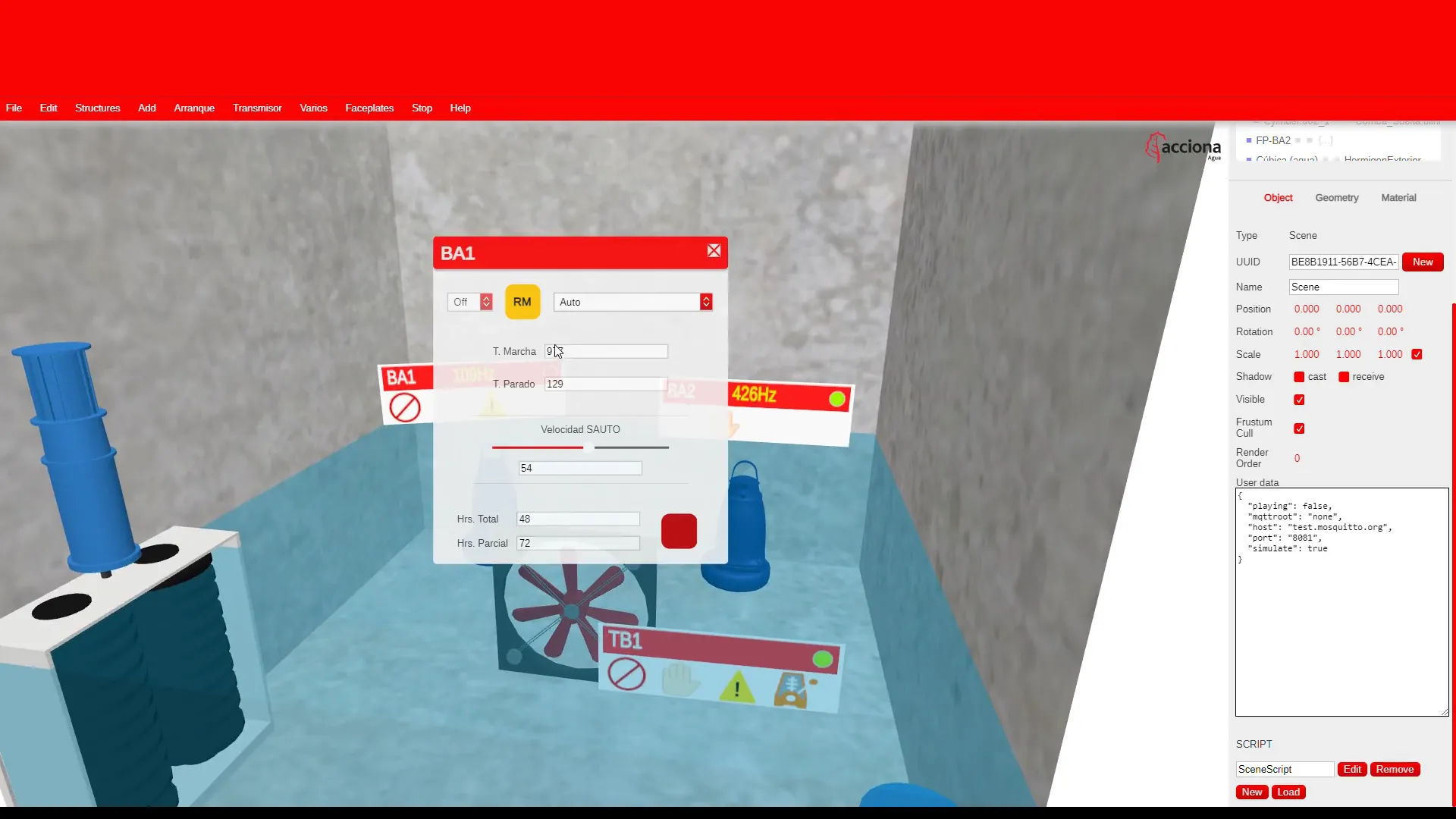

The objective of this project was to develop a system that would allow real-time verification of the operation of water treatment plants.

To achieve this, Acciona partnered with DeuSens to develop a web tool that generated interactive 3D maps connected in real time to the facility's components via sensors and IoT connections. This customized tool allowed Acciona to visualize and check the operation of the water treatment plants more efficiently, thanks to a 3D visual dashboard and control panel. All this made it possible to improve the management and maintenance of the purification plants.

Telefónica's extended stand at MWC 2023

The booth was not just a physical space, but a portal to a universe of technological possibilities. Using a Hololens 2 device, visitors could interact with immersive content integrated into the physical space. In addition, innovative technology demonstrations were presented, including 3D holographic telepresence, smart agriculture, immersive Virtual Reality experiences, a digital twin for Industry 4.0, and package delivery with 5G drones.

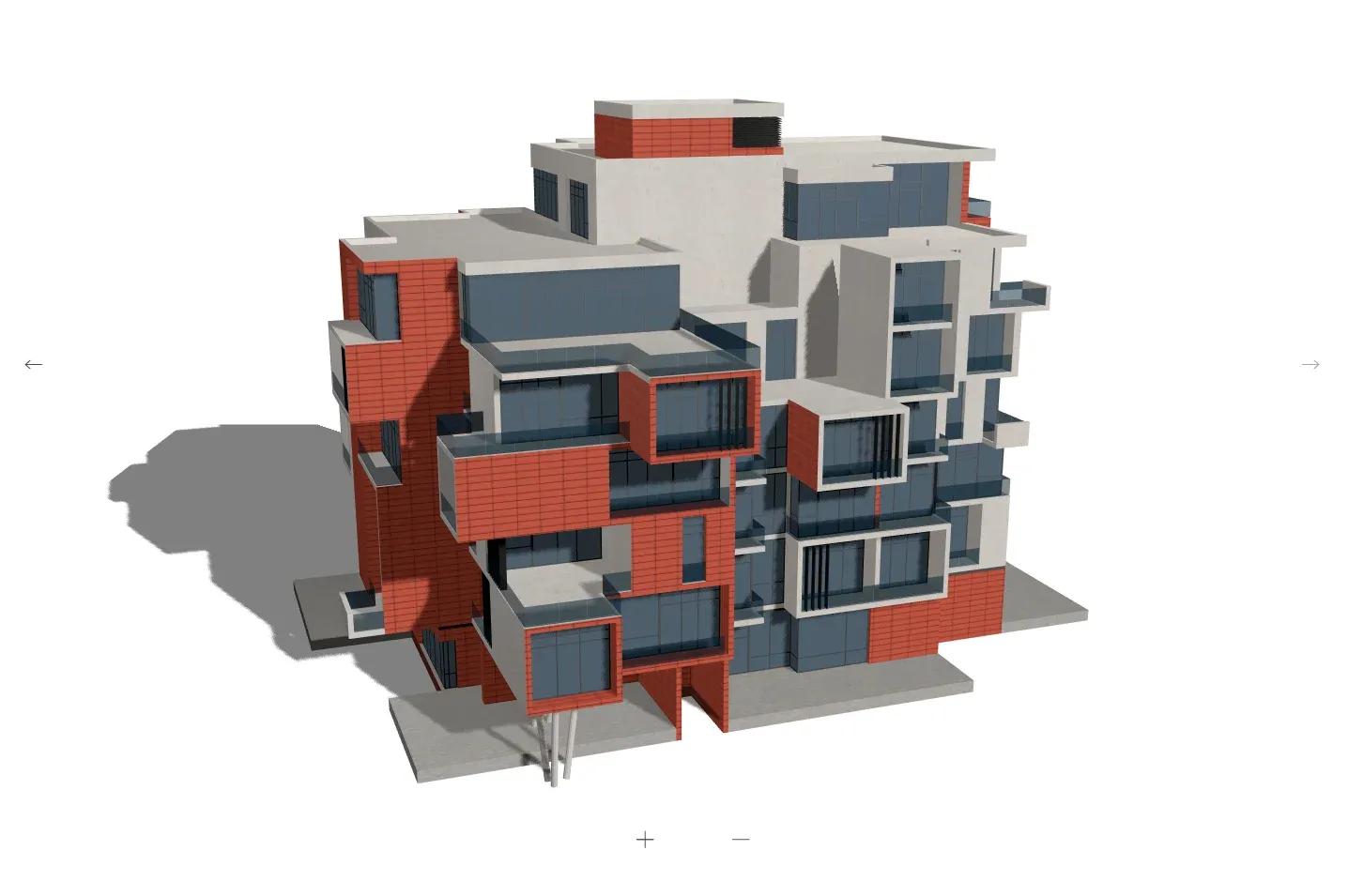

3D visualizer and building configurator for the web

In order to facilitate and guide customers through the purchasing process, allowing them to configure their customized solution, Faveker relied on DeuSens to develop a 3D web configurator.

It allowed customers to visualize products and customize features such as size, orientation, materials and colors. With an intuitive interface, customers accessed the 3D Viewer in any browser, browsing the entire catalog without external downloads. The Viewer 3D optimized Faveker's sales process by offering hyper-realistic visual stimuli and an amazing experience. In addition, the tool improved the connection with customers, allowing them to visualize how the selected porcelain stoneware would look.

Digital Twin with Mixed Reality for water pump maintenance

The Vancouver Airport Authority (VAA) partnered with Unity to implement digital twins at Vancouver International Airport (YVR).

These digital twins improved operations by providing real-time and historical 3D data, streamlining workflows and optimizing collaboration. The integration of the digital twins helped YVR predict passenger flow and allocate resources more efficiently, improving operational management decision making.

Acciona: Mixed Reality for water pump maintenance

This Hyperexperience, carried out by the DeuSens team, overlayed a virtual 3D replica of the real physical pumps, which was visible to the operators through the use of Mixed Reality glasses. In this way, technicians viewed a virtual recreation and received animated 3D instructions for maintenance. The full-scale representation of the parts and the gestural and voice interaction speeded up the work without using their hands, which made it possible to integrate this technology into training programs. And so, technicians in training learned through 3D rendering without relying on other technicians to supervise them.

Future of digital twins in industry 5.0

In Industry 5.0, digital twins play a key role in the transformation and evolution of business operations. As we move towards a highly connected and automated environment, digital twins will become an indispensable tool for process optimization and strategic decision making. They will become even more sophisticated and comprehensive, enabling the recreation and simulation of physical objects, processes and entire systems.

In the future, we will see emerging trends in the field of digital twins, such as integration with technologies like the Internet of Things (IoT), Augmented Reality (AR) and Artificial Intelligence (AI). These integrations will enable greater automation, interconnectivity and real-time data analytics, which will improve decision-making and operational efficiency. In addition, digital twins are likely to become more accessible and easier to implement, thanks to advances in cloud computing and digital twin development platforms. This will enable companies in different industries to leverage the benefits of digital twins without requiring significant investment in infrastructure and resources.

Frequently Asked Questions

-

What is a digital twin?

A digital twin is a digital replica of a product, service, process, or an entire company. -

How do digital twins work?

Digital twins work through three key elements: data, models, and algorithms. Data comes from sensors and other data collection devices. Models represent the relationships between the different elements of our business. Algorithms allow us to simulate, predict and optimize. -

How can digital twins benefit my company?

Digital twins can improve operational efficiency, enhance decision making, and foster innovation in your company. -

How are digital twins created?

Creating a digital twin requires three key elements: data, models, and algorithms. Data comes from sensors and other data collection devices. Models represent the relationships between the different elements of our business. Algorithms allow us to simulate, predict and optimize. -

Are digital twins just a fad?

No, digital twins are a long-term trend in the business world. This revolutionary technology will allow companies to always be at the forefront. -

What is the future of digital twins in business?

Digital twins are the future of business. They will allow companies to always be at the forefront, maximizing their efficiency and profitability.

Conclusion on digital twins

Digital twins are going to play a crucial role in Industry 5.0, giving companies a competitive advantage in an ever-changing business environment.

They are also a powerful tool that is revolutionizing the way we do business. By enabling companies to simulate, predict and optimize their processes, this technology gives them the opportunity to always be one step ahead, to adapt more quickly to change and to maximize their profitability.

For this reason, to take full advantage of the benefits of digital twins, it is important for companies to adopt a mindset focused on data and digitization, and keeping in mind that digital twins are not just the future of business; they are already the present.

SIMILAR CONTENT

RETURN

RETURN